VIDEO: Laser cleaning of copper contacts

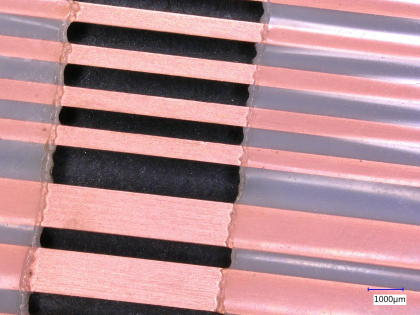

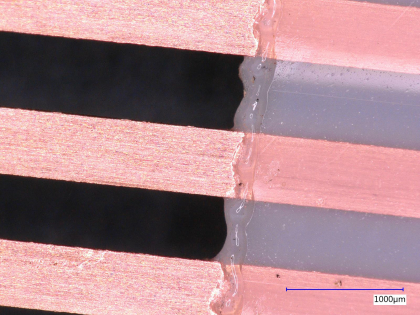

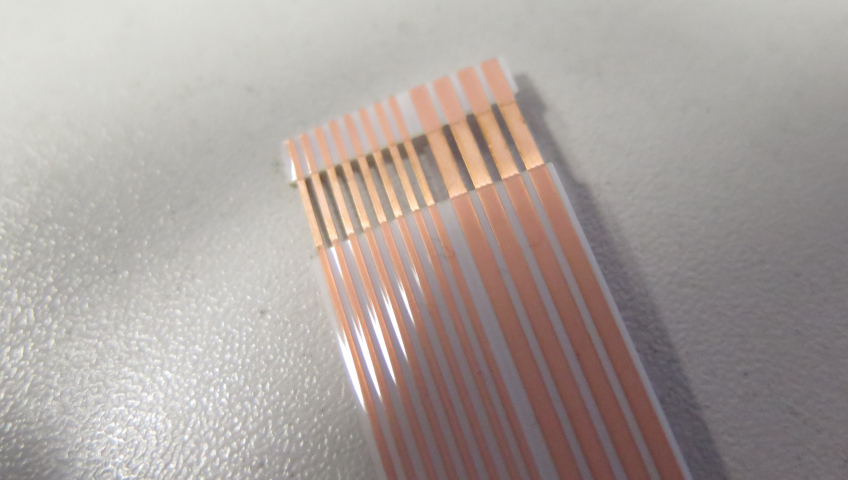

According to the customer's needs, we tested the possibility of laser cleaning of copper strips laminated in plastic. The locally stripped copper conductors are then used as a contact point.

Using a relatively low power CO2 laser (50W) we were able to effectively remove the laminated areas and prepare the copper conductors for contact. The application is carried out in a total time of less than 5 seconds, where the laminate is gradually vaporized from both sides with intensive extraction of the fumes generated during the process.

Since a deflection head was used for the application, allowing the laser beam to be guided at a defined speed over the surface of the part, the position of the laser and the sample itself can remain constant during the process. The slightly sealed edges of the cleaned area do not have a significant negative effect on the contact function.