TESTING: Laser welding of nickel strips to battery cells

The company Asahi Consulting EP&S s.r.o. she contacted us on the basis of the recommendation of one of her partners, who already had cooperation with LINTECH, spol. s r.o. good experience.

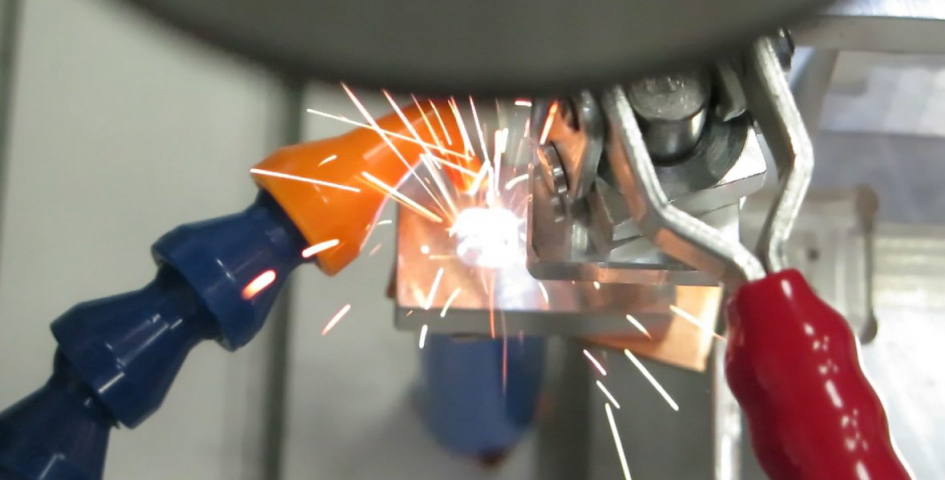

The subject of demand was laser welding of nickel strip to standard battery cells. As in all similar cases, after providing basic information about the application, we agreed to prepare test samples.

Gentlemen Bc. Kamil Nyklíček and Radek Laštovička from ASAHI also expressed interest in participating in the testing in person. According to the usual practice, they sent samples in advance for the evaluation of feasibility. The next step was to perform initial tests and prepare the foundation and pressing agent.

After receiving the samples and performing these preparations, a joint meeting took place in our application laboratory under the baton of an application specialist, Ing. Routines. Using our know-how, based on the patented procedure of the laser module manufacturer SPI, we performed a series of documented tests with various parameters.

The main criteria were the quality and strength of the welds as well as the speed of processing. The tests were performed on battery cells from leading manufacturers LG and SAMSUNG using nickel strips of two different thicknesses.

Gradual optimization succeeded in achieving a quality circular weld with a diameter of 2 mm in 0.8 s and, of course, with the required strength of all welds. For the application, we used a pulsed fiber laser assembly with a deflection head and an F-theta lens.

We were mutually satisfied with the course of testing and the results. The gentlemen at ASAHI especially appreciated the approach of LINTECH employees and the care they received. They were also very pleased with the speed of negotiations and the performance of the tests themselves.