VIDEO: Robotization in conjunction with laser technology

Over time, views on automation and robotics have changed, as has the pandemic caused by COVID-19. This virus has caused production problems for many companies. In order not to spread the disease, companies were forced to suspend operations, often for up to 3 months, which led to hundreds of millions or billions of financial damage. Most operators were forced to be at home or in quarantine and production stagnated.

Currently, manufacturing companies are betting on robotics and automation - resources that can replace scarce and expensive labor. Robotization of production processes brings a number of indisputable advantages, such as increased productivity, production flexibility and better quality of the final product. The return on the initial investment will be recouped within a few years.

Connection of robot and laser by LINTECH

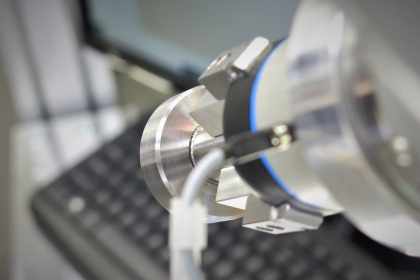

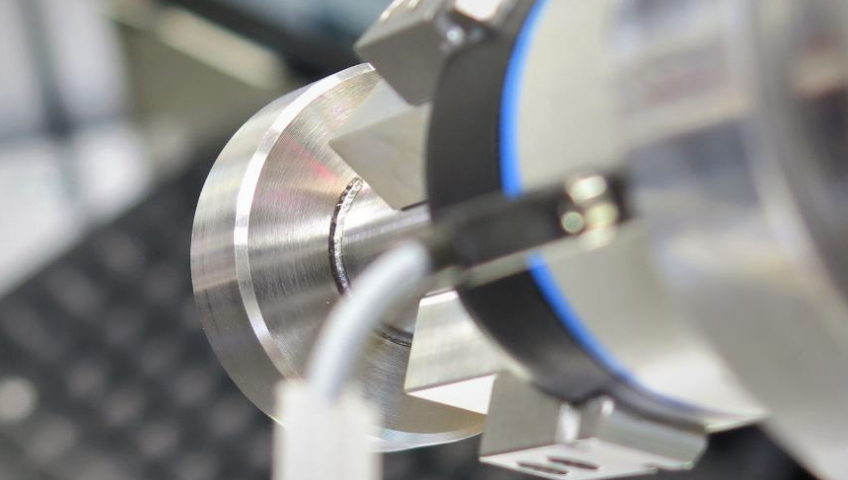

LINTECH is a supplier of custom laser equipment. From the design and debugging of the laser application in a richly equipped application laboratory, through the construction of the machine to warranty and post-warranty service. It also offers the possibility of integrating an automated workplace in conjunction with a laser and a Stäubli robotic arm, which is the most optimal for laser accuracy.

Thanks to the technological background of LINTECH, we managed to prepare a demonstration of laser welding of steel parts using a robotic arm. The company's background provides a wide range of laser modules, from which a 300 W QCW laser was selected as the most suitable for this application. The advantages of laser welding of metals are:

- easily achievable narrow and deep weld on a wide range of materials

- laser welding takes place with very little energy input per unit

- lengths, resulting in minimal deformations, low residual internal stresses caused by welding and a small heat affected zone

- the inertia of the laser beam is very short, laser welding is therefore suitable for automation

- the laser beam can be welded locally even in hard-to-reach places where it would be difficult by other welding methods

- non-contact welding method

- high weld quality

- higher penetration depth

- targeted, small and well-localized heat load

- welding at high temperatures

- possibility of 3D contour processing (high flexibility)

- the result is wear-resistant

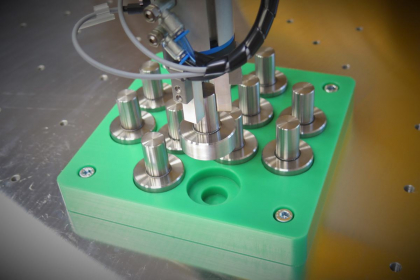

LIN-bot exhibit - automated workplace

Every year, LINTECH representatives visit the AMPER and MSV trade fairs, where they present a fully automated robotic LIN-bot workplace. Unfortunately, due to the pandemic associated with COVID-19, trade fairs are not taking place this year, which is why we offer you a short video for a better idea and understanding of the function of the automated robotic workplace.

LIN-bot is used to describe anodized labels with the help of a micro-impact device and a laser safety head, which was developed by LINTECH. An integral part of the cell is the camera, thanks to which the robot itself is able to find an arbitrarily based label and start the marking cycle. Using a laser safety head with a LSS - F70 P laser, a QR code is marked on the label, the accuracy of which is verified by a reader.

If you have any questions, please contact a technical-sales representative.