New in LINTECH application laboratory - 300 watt pulsed laser

In order to remain competitive at LINTECH, we continuously invest in technical equipment of our own application laboratory. Thanks to it, we are able to demonstrate on prototypes the entire process of technology integration and the functionality and efficiency of the machine under development. At the same time, we offer our customers a wide range of tests to verify the utility properties of the incorporated materials and the feasibility of laser applications.

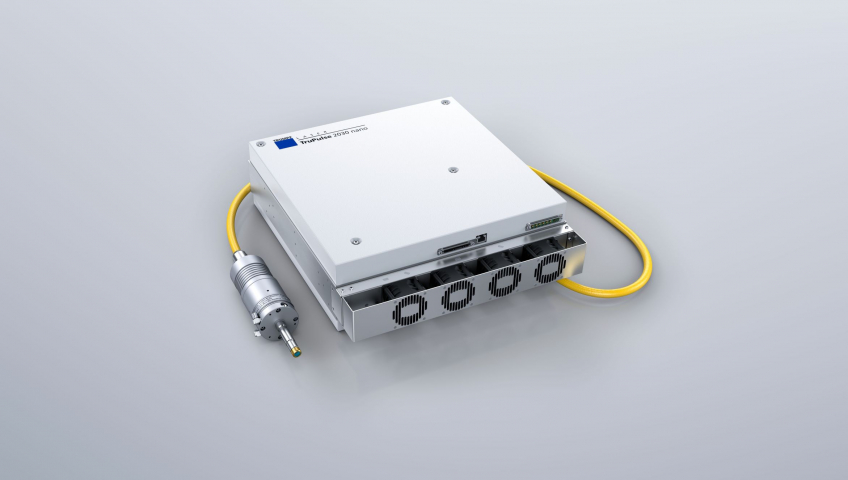

This time we have expanded our existing technological equipment with a 300 Watt nanosecond laser system from Trumpf, which until recently was one of the most powerful air-cooled pulsed fiber lasers on the market. The newly purchased laser source opens up new application possibilities in the field of thin sheet metal cutting, welding of heterogeneous materials or surface cleaning. The advantage here is the possible use of high power, which, combined with high repetition rates and scanning speeds, enables a several-fold increase in productivity. Examples include spot welding of copper contacts (copper-copper) up to 0.5 mm thick in sub-units of seconds.